The digital era of the physical world is surging forward. 2D and 3D visual technologies convert information such as color, shape, size, size, and position of objects into big data in the AI era, but the digitization process of material components has stalled.

Nowadays, the revolutionary visual imaging technology that can decode the "fingerprints" of everything - hyperspectral imaging - is breaking this deadlock.

Hyperspectral imaging breaks through the limitations of the human eye and can detect the composition of everything, providing more realistic and accurate physical world information for machine vision, and providing humans with a higher dimensional way to observe the world.

Recently, media outlets such as Southern Daily have continued to focus on the micro hyperspectral imaging MEMS chips and the rapidly growing hyperspectral imaging market of Hypernano (hereinafter referred to as "Hypernano"). From focusing on research and development to the engineering and marketization of hyperspectral products, behind Hypernano's crossing of the startup company's "Death Valley", it reflects the breakthrough of domestic MEMS sensors in the global high-end sensor arena.

The following is the report content:

Recently, the reporter learned from Hypernano (referred to as Hypernano) in Shenzhen that in early 2022, the company announced that it was officially the world's first to mass produce the first generation of micro electro mechanical systems (MEMS) sensors for hyperspectral imaging. Hypernano industrial cameras and hyperspectral camera modules are about to be launched into the market.

▲Hypernano optics

It is reported that based on micro hyperspectral imaging MEMS technology, the hyperspectral imaging module launched by Hispectral has reached a global leading level in professional technical indicators such as wavelength accuracy, shooting speed, spatial resolution, half peak width, and field of view angle. Its volume has been reduced by nearly 1000 times compared to traditional spectral cameras, making it the smallest hyperspectral camera module in the industry.

01. Semiconductor Veteran Shenzhen Entrepreneurship Leaps Over the "Valley of Death"

Huang Jinbiao, founder and CEO of Hypernano, introduced that the company was founded in January 2019 with the mission of "4D super perception, everything can be measured", focusing on the design and development of hyperspectral imaging technology.

▲Huang Jinbiao

Huang Jinbiao graduated from Nankai University with a major in microelectronics and over 20 years of semiconductor technology and market experience. He has served as a senior executive in multiple semiconductor companies and has strong experience in system development and market exploration.

The Hypernano R&D team has nearly 20 years of experience in MEMS design and manufacturing in the field of MEMS. The core members of the team include several top MEMS experts and Shenzhen Peacock talents.

In March 2022, Hypernano completed a round A financing of tens of millions of yuan, with investors including Kunlun Capital, Yuanyuan Capital, and Wanxin Capital.

Industry insiders introduce that MEMS chips are most commonly used for sensing functions, which are somewhat similar to human sensory systems in the entire large information system.

In terms of industry, Europe and the United States are the birthplace of the MEMS industry, technology, and products, and are in a global leading position. China's MEMS industry started relatively late, and the MEMS industry is still in its early stages of development. China not only has a huge gap in performance indicators such as accuracy and sensitivity compared to foreign countries, but its application scope is also mostly limited to mid to low-end fields. Therefore, there is a saying that sensor entrepreneurship is difficult, and MEMS sensor entrepreneurship is even more difficult.

However, although MEMS sensor manufacturers in China face many challenges, there is huge room for domestic substitution in areas such as upstream design, midstream manufacturing, and downstream packaging.

▲Hypernano Micro Hyperspectral Imaging MEMS Chip

It is precisely because of its position in the MEMS industry, a highly sophisticated and cutting-edge industry, that Hypernano has gone through the "Valley of Death" test faced by high-tech startups in its early three years, from technological research and development to product mass production.

No matter how advanced the technology of a startup company is, it must also be turned into an engineering and market-oriented product. There are many pitfalls in this process, and only by stepping forward can technology have commercial value. "Huang Jin declared.

Huang Jinbiao introduced that by the end of last year, Hypernano had started mass production of its core technology. At the same time, the relevant modules for applying it to cameras have also been prepared, which is equivalent to the company's biggest hurdle in the field of technology engineering products for start-up companies, and it has already crossed the threshold.

02. Fill the gap in the field of micro hyperspectral MEMS in China

When it comes to spectroscopy technology, the first step is to popularize spectroscopy technology.

Spectroscopy originated from the British scientist Newton and was an important way for humans to perceive the world through light. Different elements and compounds on Earth have their own unique spectral characteristics, and spectra are therefore considered as information that can distinguish the composition of substances.

One of the biggest features of spectroscopy is the study of the interaction between light and matter. Through physical methods, the composition of objects can be obtained, and in applications, non-contact and non-destructive detection can be carried out. Typical materials such as astronomical objects, high-temperature objects, and discharge gases are analyzed and studied at the molecular and atomic levels, mainly using spectroscopic methods. For example, humans use spectroscopic cameras to capture the surface matter of distant planets.

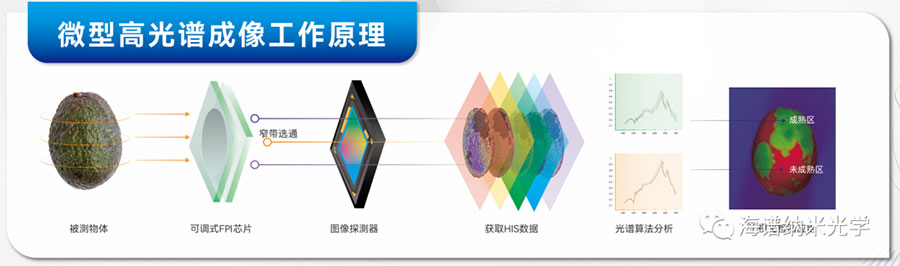

▲Principles of Micro Hyperspectroscopy

Huang Jinbiao introduced that hyperspectral imaging technology combines imaging technology with spectral technology to obtain continuous and narrow band image data with high spectral resolution. The principle is to combine imaging technology with spectral technology, while detecting two-dimensional spatial information of the target, to obtain spectral information at each spatial position, thereby achieving direct detection of material components.

The spectral information of substances has fingerprint characteristics, that is, different substances have different spectra. Therefore, hyperspectral imaging provides a new path for material perception, recognition, and analysis in machine vision, and is the next revolutionary visual imaging technology after 2D and 3D vision technologies.

In 2019, after its establishment in Shenzhen, Hypernano began the research, development, design, and fabrication of the first micro hyperspectral imaging MEMS sensor. At the beginning of 2022, Hypernano announced the official mass production of the first generation of micro hyperspectral imaging MEMS sensors, filling the gap in the field of micro hyperspectral imaging MEMS sensors in China.

Traditional spectral imaging equipment is generally manually assembled, which has problems such as large volume, high price, and inability to produce in batches. The marine spectral micro hyperspectral imaging MEMS sensor has performance advantages such as high spatial resolution and high transmittance, solving problems such as the volume and cost of spectral imaging equipment; Mass production can also effectively reduce the inter stage difference of hyperspectral imaging equipment, achieving fully automatic assembly from chip to machine.

As a result, Hispectral has achieved a breakthrough in MEMS special processes, solving the industry challenges of industrialization, low-cost, and mass production of hyperspectral imaging. Its research and development capabilities cover the entire hyperspectral chain technology, including chip design, optical modules, product cameras, algorithm research and development, and complete application solutions. It can provide one-stop hyperspectral imaging solutions for customers in multiple fields worldwide.

Traditional spectral imaging equipment is a big instrument; the camera module of Hypernano is only one nail large and cheaper, surpassing the threshold of civilian use in terms of volume, price, and convenience. It is also China that has achieved a world leading position in this segmented track, "Huang Jinbiao compared.

▲Hyperspectral imaging technology can detect the composition of substances

03. Chip products cover all spectral bands, making everything measurable

At present, the company has launched several products, forming full spectrum coverage and achieving measurability for everything.

Huang Jinbiao introduced that hyperspectral imaging MEMS sensors and modules can be applied in multiple scenarios such as industrial testing, medical health, security and environmental protection, food testing, IOT, etc.

For example, in the field of industrial testing, hyperspectral technology can achieve functions such as food detection and sorting, quality level screening, etc. in a non-contact manner. Previously, detection results in minutes or hours can now be obtained in real-time online.

In medical health, hyperspectral devices can endow ordinary microscopes with hyperspectral visual ability, while also achieving functions such as cancer screening and surgical assisted imaging.

In the field of security and environmental protection, hyperspectral technology can monitor water quality and environment in real time, achieve qualitative and quantitative observation of water quality, and achieve cloud visualization effect.

In the field of food testing, hyperspectral imaging technology can perform material analysis on meat, fruits and vegetables, grains and oils, detect indicators such as sugar content, moisture content, hardness, acidity, etc. of fruits and vegetables, and intelligently analyze the freshness of meat.

It is worth noting that Hypernano not only has a hardware team, but also an AI algorithm team, which ensures that data can be calculated and modeled to obtain consistent results.

Why can a nameless startup technology company fill the gap in the hyperspectral MEMS sensor industry and achieve global technological leadership?

Huang Jinbiao introduced that hyperspectral imaging MEMS sensors are a multidisciplinary technological breakthrough, involving not only microelectronics, but also chemistry, materials, mechanics, optics, and more. However, the company has always focused on the sub field of hyperspectral imaging technology, and the core R&D team of the company has focused on the research and development of this sub technology for the past 20 years, with a world leading technological precipitation.

China is temporarily lagging behind foreign countries in this area, but in reality, the accumulation is not enough. In addition to capital, policies, and market support, many scientific researchers and engineers need to work hard in the laboratory and production line for years and months in order to have leading technological breakthroughs. "Huang Jinming, as a veteran who entered the semiconductor industry after graduating from university in the 1990s, witnessed the emergence, development, and prosperity of the semiconductor industry in Shenzhen in the past 20 years, We hope to support domestic technology to achieve more breakthroughs in semiconductor "unmanned zone" technology through independent technological innovation.

We have always stressed that whether a technology is progressiveness and breakthrough, it must be useful and provide recognized solutions for the market and consumers.

Hypernano combines micro hyperspectral imaging MEMS sensors with artificial intelligence algorithms to translate the composition information of objects for consumers. For example, when we take a piece of meat with our human eyes or a regular camera, it is a regular photo. However, the photo taken by the camera with our chip installed will be read by an algorithm and converted into a result that is understandable to ordinary people, telling you whether the meat is fresh.

We insist on not making end products. Nowadays, there are many globally renowned hardware terminal product companies in China, especially in Shenzhen. Our positioning is to produce high-end testing equipment and solutions to serve these hardware terminal product companies.

In our view, China's current bottleneck is due to the lack of upstream core chip or device technology and manufacturing capabilities. Hypernano is determined to play such a role.

——Deep creators say @ Huang Jinbiao

Reporter: Li Ronghua

【 Overall planning 】 Qu Guangning

[Image] Li Ronghua, partially provided by respondents

——The above content is from "Southern Plus", and the title and content have been modified